HILLSBORO, Ore. — While the Portland metro area continues to grapple with long-term affects of the COVID-19 pandemic, a report released last week by the Portland Metro Chamber found that, from a jobs perspective, the area can now be considered fully recovered.

The challenge now for state officials and business leaders is to keep job growth going into the future — and major efforts to invest in Oregon's "Silicon Forest" and a suitably prepared workforce are supposed to do just that.

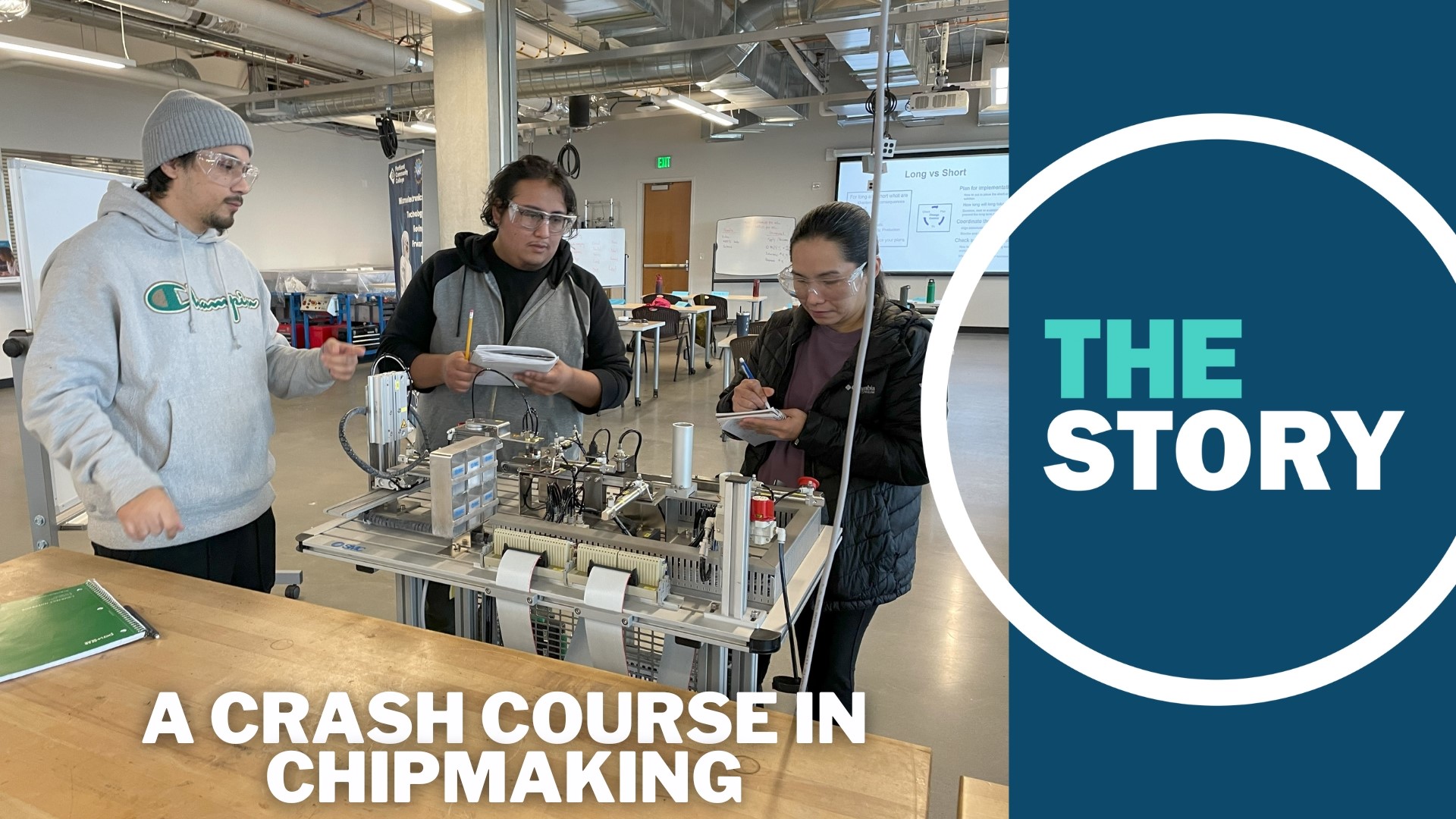

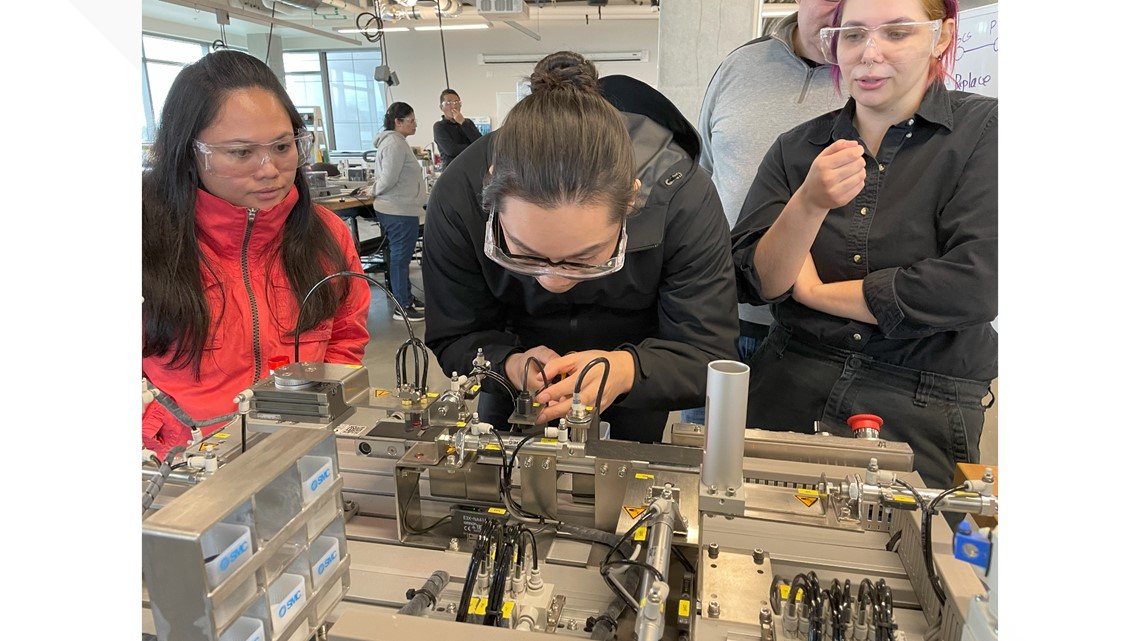

In a classroom at Portland Community College's Willow Creek Center, parts of the high-tech machines used to create silicon chips sit quietly now, but over the last two weeks they revealed secrets to students — secrets about how they worked, and how they could be fixed.

For some, like Kyra Rodak, studying these machines unlocked a door to the future.

"I heard about it, I was previously working retail and I wanted to move into more a manufacturing industry," Rodak said.

Rodak said she was intimidated at first, but then saw past her fear.

"I would really recommend it," she said. "I was definitely nervous going into it. You know, coming in and working with hand tools and being like, 'I don't know what I'm doing.' But having other people there who also didn't know what they were doing and getting to learn together — I think it's a great opportunity and its not as intimidating as it sounds."

Rodak is one of a group of graduates now finishing a two-week free program called Quick Start. It teaches the basics of fixing the machines that create silicon chips.

Instructor Steve Dufresne explained that Moore's Law, which suggests that the speed and capability of computers can double every two years, continues to drive both change and the need for workers who can fix the next generation of machines.

"It's resulted in the tools getting more complex. So, how we have to work on this ... the types of techniques being used are getting harder," he said. "It means the tools are getting bigger. And as the tools get bigger they need more maintenance, and that means more jobs for people that do that maintenance. So it's not a field that's going away."

The class is a collaboration between Intel and the city of Hillsboro, Washington County and the state of Oregon. PCC President Adrien Bennings said it's a great opportunity.

"Some of the things that I really value about the program is that they not only have the opportunity to participate in a two-week program offering a $1,000 stipend," Bennings said, "but also having a pathway to either going on into the workforce — having an entry-level interview with a local employer — or also continuing their education through our associate's degree program, microelectronics, or our one-year certificate program. So I ground this all in terms of two words: impact and opportunity. That's what today means."

Jesus Zavala is another graduate of the program. He ended up here because of a caring brother.

"Mainly my brother put me in this place because he thought it was a good opportunity," Zaval said. "And he's right, it is a great opportunity to learn something that you are passionate about. Which I am."

Zavala said he loved learning about hydraulics, pneumatics and everything else the machines had to offer. He sees the knowledge as a ticket to a better life.

"Oh, it's life-changing," he said. "It's probably one of the best things to happen the past few years, 'cause I'm from a poor background and I didn't have the chance to go to college. And this place will make my life way easier."

Intel has hired 111 people from the Quick Start courses so far.

Diane Vidmantas is the director of business operations for the Tech Development Division at Intel. In her view, the PCC program is a win-win; without the people who keep Intel's equipment running, there would be no future here.

"They really are the lifeblood of our factory. They work on our equipment and make sure they are humming along creating our chips," Vidmantas. "And without that locally we wouldn't have a factory here."